NAM LONG CONSTRUCTION AND PRODUCTION INVESTMENT LIMITED COMPANY – PIONEER IN TECHNOLOGY SOLUTIONS

DESIGN PROCESS AT NAM LONG COMPANY

25/02/2024

ERECTION PRINCIPLES OF NAM LONG COMPANY

25/02/2024As a steel structure company with many years of experience in the construction industry of pre-engineered steel buildings and steel structure projects in Vietnam, Nam Long always strives to bring better solutions to customers. Today we will introduce to customers the technologies that we are applying to projects.

Design software is updated annually

Modern steel structure design and calculation software helps speed up the design process significantly. Our design engineers use this software to quickly calculate bearing points, cavity spacing, roof slope, load and weight of steel frame members. The software then creates concise production drawings for each section of the steel frame accurately and specifically. This helps the production phase go smoothly and shortens processing time.

Nam Long Company always updates the most modern software on designing prefabricated steel buildings and steel structures: CFS purlin design, Tekla deploys the latest production and construction drawings, etc.

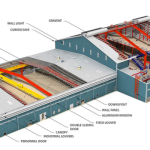

Modern technology for locating anchor bolts at the construction site

One of the most common mistakes in steel building construction today is incorrect placement of anchor bolts. Once the BIM model is completed, the anchor bolt location drawings can be exported to the Trimble Field Link for Structures tablet – which when interfaced with the Robotic Switchboard (RTS) will enable field layout accuracy of points to verify. Once the anchor bolts have been placed, the RTS system can be used to confirm the exact location of the anchor bolts, comparing the actual position with the position in the BIM model.

Access to modern covering materials

We recommend that customers use corrugated iron sheets with modern paint technology with highly reflective paint and good heat reflection ability. These corrugated iron panels help save energy in hot climates like Vietnam and tropical areas. They help reduce cooling energy costs by up to 15%.

Streamlined process for steel structure production at the factory

We improve and streamline the steel structure production process at the factory every day. This is aimed at providing high quality products, shortening production time and avoiding waste at the lowest cost of raw materials. Steel structures are manufactured and assembled on site or combined with the latest construction materials such as precast reinforced concrete and composite concrete. Lean production and automation methods are commonly applied at Nam Long such as computer numerically controlled welding and drilling machines and software controlled milling machines.