DESIGN PROCESS AT NAM LONG COMPANY

QUALITY POLICY OF NAM LONG COMPANY

25/02/2024

NAM LONG CONSTRUCTION AND PRODUCTION INVESTMENT LIMITED COMPANY – PIONEER IN TECHNOLOGY SOLUTIONS

25/02/2024Nam Long Company is a reputable steel structure and pre-engineered steel building contractor in Vietnam. In this article, we will introduce the professional design process at the company to bring quality projects in terms of products, services and construction time.

Design process at Nam Long company

The design phase begins after the contract has been signed and project implementation has begun. During the design phase, Nam Long’s team of experienced engineers will design different drawings to serve production at the factory and erection at the construction site. We design according to the latest pre-engineered steel building and steel structure standards.

Besides, all drawings are designed with modern software and continuously updated to calculate accurately and optimally, helping to save steel materials. Since its establishment, the company has successfully designed and put into use many diverse projects on steel structures and pre-engineered steel buildings. At the same time, Nam Long’s products have been exported and are present in Southeast Asia, America, Europe… We are capable of providing optimal solutions for many types of projects such as factories, warehouses. , industrial buildings, commercial centers, public buildings…

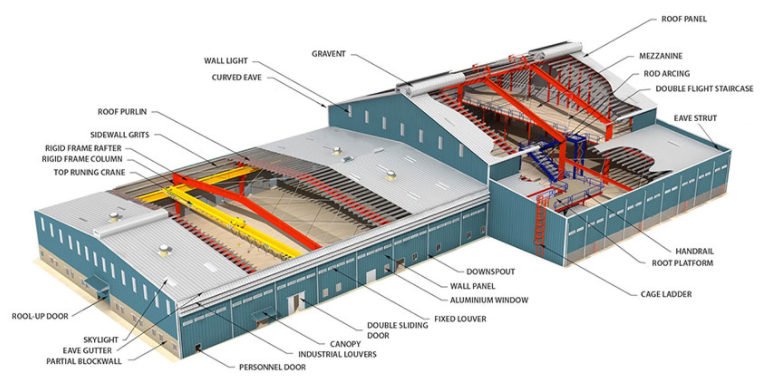

Types of drawings in the project design process of Nam Long company

Technical design: shows what technical elements the project will have, as well as technical materials for each different component. Technical design is the backbone of the project. The results of this stage are architectural drawings and steel structure drawings

Production design: so that the factory can accurately process components and accessories, drawings from the engineering stage will be transferred to production drawings. Drawings need to show fully and in detail the size, quantity, shape, and technical requirements of each component.

Installation design: describes the factory floor plan, requirements and erection location. Factory steel structures require high precision in erection to ensure sustainable construction.

Factors to consider in designing steel structures

Pre-engineered steel buildings and steel structures have been used in most industrial applications, becoming the top choice of investors, business owners of factories, workshops, warehouses, etc. Steel structure solutions bring outstanding advantages over traditional construction methods in cost savings, erection time savings, environmental friendliness and flexibility in space layout.

Factors that Nam Long’s engineering team needs to discuss with customers before we make drawings:

- Use of the project: need to determine what type of industry this project is for (steel production, garment and textile, food, pharmaceuticals…). Because pre-engineered steel buildings are a type of project that is specifically “tailor-made” for each business. Therefore, with rich experience in erecting diverse types of projects in many industries, Nam Long’s engineers will advise and provide appropriate solutions for the project’s intended use.

-

Area, architecture, construction location: usually the larger the area, the lower the cost per square meter of the project. However, this also depends on the level of architecture the business owner wants to implement as well as the geological structure and weather at the factory construction site.

-

Project budget: One factor that cannot be overlooked is the project budget. Depending on the size of the budget, the company’s engineers will propose appropriate solutions and materials. At the same time, we can further advise customers based on the budget to decide on the necessary and important items of the project. This helps investors save time and costs during project implementation.